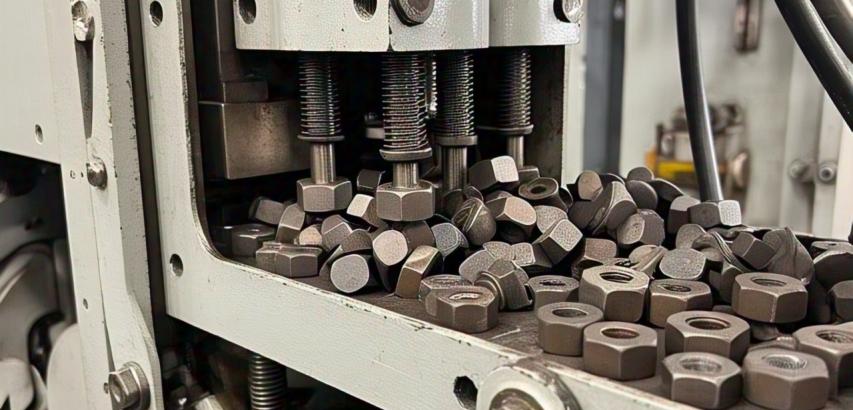

An iron nuts machine refers to industrial equipment designed to produce metal nuts—hexagonal or square fasteners with internal threading—used to secure bolts in construction, automotive, machinery, and other applications. These machines automate the forming, threading, and finishing of nuts, ensuring high precision and efficiency in mass production.

Types of Iron Nut Manufacturing Machines

Cold Heading Machines:

Process: Feeds iron or steel wire into dies, where it is cut, shaped, and punched into a blank nut.

Key Components: Wire feeder, cutter, header punch, and forming dies.

Output: Produces nut blanks (unthreaded) at high speeds (100–500 pieces per minute).

Thread Rolling Machines:

Process: Uses hardened dies to press threads into the blank nut via cold forming.

Advantages: Creates stronger threads than cutting, with no material waste.

Types: Flat-die or planetary thread rollers.

CNC Nut Tapping Machines:

Process: Cuts internal threads into pre-formed blanks using rotating taps.

Use Case: For low-volume or custom threading.

Secondary Processing Machines:

Heat Treatment: Annealing or hardening nuts for durability.

Plating/Coating: Electroplating (e.g., zinc, nickel) for corrosion resistance.

Quality Control: Vision systems or gauges to check dimensions and threads.

Key Components of a Nut-Making Machine

Wire Straightener: Prepares coiled wire for feeding.

Feeder Mechanism: Advances wire to the cutting station.

Forming Dies: Shapes the nut’s exterior (hexagonal/square).

Threading Unit: Adds internal threads via rolling or tapping.

Ejection System: Removes finished nuts from the machine.

Production Process

Wire Preparation:

Coiled iron wire is straightened and lubricated.

Blank Forming:

Wire is cut to length and cold-headed into a nut shape.

Threading:

Thread rolling dies or taps create internal threads.

Finishing:

Deburring, heat treatment, and surface coating.

Packaging:

Nuts are sorted, counted, and packed.

Applications

Construction: Structural steel fastening.

Automotive: Engine components, chassis assemblies.

Machinery: Industrial equipment assembly.

Consumer Goods: Furniture, appliances.

Material Considerations

Low-Carbon Steel: Most common due to strength and formability.

Stainless Steel: For corrosion resistance (e.g., marine environments).

Iron: Less common today due to brittleness; often replaced by steel.

Challenges

Tool Wear: High-pressure forming and threading degrade dies over time.

Thread Accuracy: Tight tolerances (±0.01 mm) required for bolt compatibility.

Material Waste: Efficient wire usage and scrap recycling are critical.

Innovations

Automated Feed Systems: Reduce manual intervention.

IoT Integration: Real-time monitoring of machine performance and predictive maintenance.

Multi-Station Machines: Combine cold heading, threading, and finishing in one unit.

Leading Manufacturers

National Machinery (USA): Specializes in cold heading and thread rolling.

Sakamura (Japan): High-speed nut formers.

WAFIOS (Germany): Precision wire-forming solutions.

Iron nuts machines are vital to global manufacturing, producing billions of fasteners annually with unmatched speed and accuracy. By leveraging cold forming, thread rolling, and automation, these systems deliver durable, reliable nuts essential for everything from skyscrapers to smartphones.

From wire to finished nut—precision engineering at its best! 🔩⚙️

|  |  |